Innovative Coil Handling Equipment

At KORE Machinery, we’re at the forefront of coil processing innovation, and we’re all about the incredible difference that advanced coil feeding equipment can make in metalworking.

Our passion for top-notch quality and cutting-edge innovation has made us an industry go-to ally. We are always ready with solutions that meet tough precision metalworking requirements.

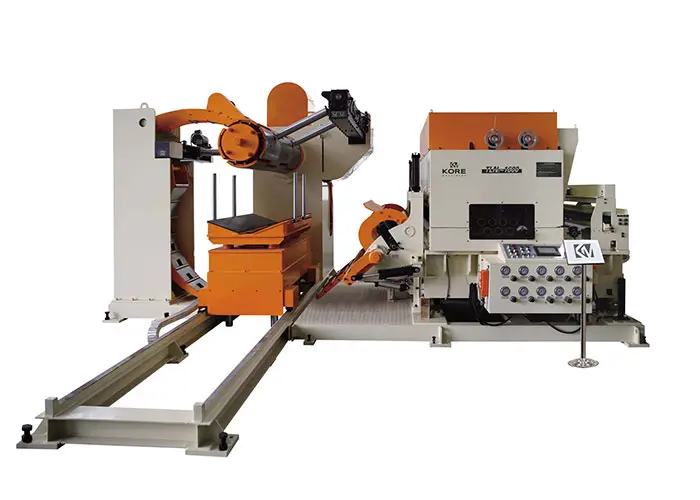

Coil-feeding equipment is the unsung hero of metal fabrication, bringing unparalleled efficiency and accuracy to the table. These systems are game-changers, smoothing the whole process from the initial uncoiling to feeding metal sheets into press machines. This ensures every piece is consistent and top-quality.

Learn more about our coil feeding machinery, including our standout products, and what to look for when buying coil processing equipment.

Types of Coil Feeding Machinery

We pride ourselves on our extensive range of coil feeding systems, meticulously crafted to meet a broad spectrum of operational demands across the metalworking industry. Our offerings are not just equipment; they’re solutions engineered with precision, designed to enhance productivity and ensure the utmost quality in every task they undertake.

Learn about the diverse types of coil feeding equipment we provide, each serving a unique purpose in the intricate dance of metal fabrication:

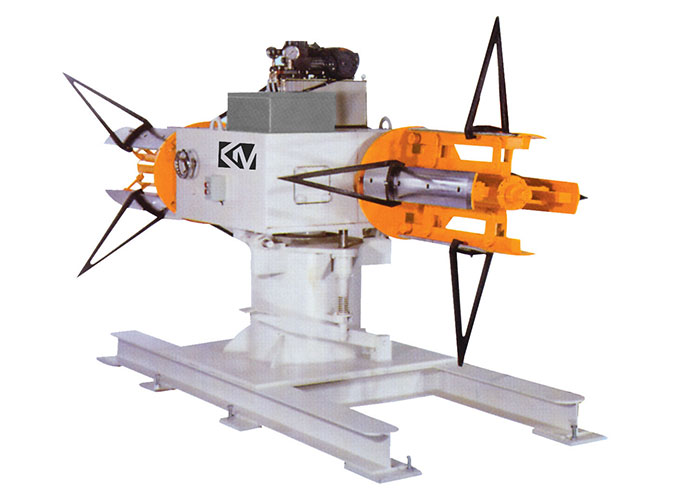

- Uncoilers: Essential for unwinding coils into flat sheets, our uncoilers are designed to integrate with your manufacturing lines seamlessly.

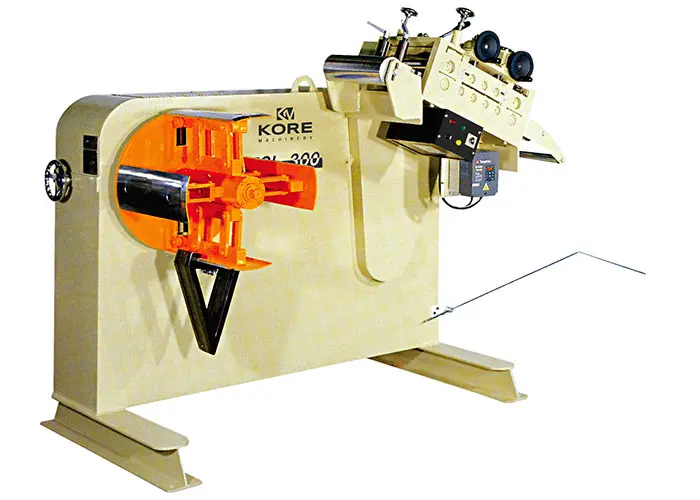

- Straighteners: These remove material imperfections and prepare sheets for processing, ensuring high-quality outputs.

- Servo Feeders: Our servo feeders offer precise control for high-speed operations, catering to industries where accuracy is critical.

- Cradle Feeders: Best suited for handling heavy coils, these feeders maintain efficiency and safety in your operations.

Key Features to Look For

Selecting the ideal coil-feeding equipment hinges on a few critical features that directly impact your operation’s productivity and product quality. Speed and precision control are paramount, and advanced systems offer real-time adjustments to keep up with the demands of high-speed production without sacrificing accuracy. This ensures a faster workflow and superior quality in your finished products.

Material versatility is another essential factor, as the ability to handle a wide range of material types and thicknesses significantly boosts the equipment’s utility across various projects. Furthermore, equipment designed for seamless integration into existing production lines is crucial for maintaining uninterrupted operations and ensuring a smooth transition with minimal downtime.

Durability cannot be overlooked. Robust construction guarantees long-term reliability and reduces the need for frequent maintenance, offering a better return on investment over time. At KORE Machinery, we focus on these key aspects to provide coil feeding solutions that enhance efficiency, ensure product quality, and integrate effortlessly with your existing setup. These solutions support your business’s growth and success in metal fabrication.

Choosing the Right Equipment for Your Application

Automation stands at the core of KORE Machinery’s innovations. Our automated coil feeding systems are engineered to enhance operational efficiency and accuracy, reducing manual labor and the potential for error, thereby streamlining the production process.

Selecting the appropriate coil feeding equipment requires a thorough assessment of your operational needs:

- Material Specifications: Consider the type and thickness of the materials you work with.

- Production Volume: Our solutions cater to various production volumes, from small-scale operations to high-volume manufacturing.

- Space Constraints: We provide equipment options designed to fit different spatial configurations.

- Investment Consideration: Our team can help you conduct a cost-versus-performance analysis to ensure the best return on your investment.

Enhancing Metal Work Precision with Advanced Coil Feeding Solutions

At KORE Machinery, our dedication to pushing the boundaries of technology shines through in our advanced coil feeding solutions. These systems are not just about feeding metal; they’re about transforming your production line into efficiency and precision.

But innovation doesn’t stop with just the creation of superior machinery. We understand maintenance and operational safety’s pivotal role in sustaining peak performance.

That’s why thorough guidelines and dedicated support services are provided for each piece of KORE Machinery equipment. We’re here to ensure your journey toward higher productivity is successful and safe. Our commitment extends beyond the sale, providing you with the knowledge and assistance needed to keep your operations running smoothly, day in and day out, fostering a safe, efficient, and highly productive environment.

Ready To Buy?

At KORE Machinery, we’re dedicated to providing our clients with advanced, reliable solutions for metal processing. Our coil feeding equipment is a testament to our commitment to innovation and quality, designed to help you achieve optimal productivity and precision in your metalworking projects.

Contact us for more information on how KORE Machinery can transform your metal fabrication process!