Cut-to-Length or Blanking: What’s the Difference?

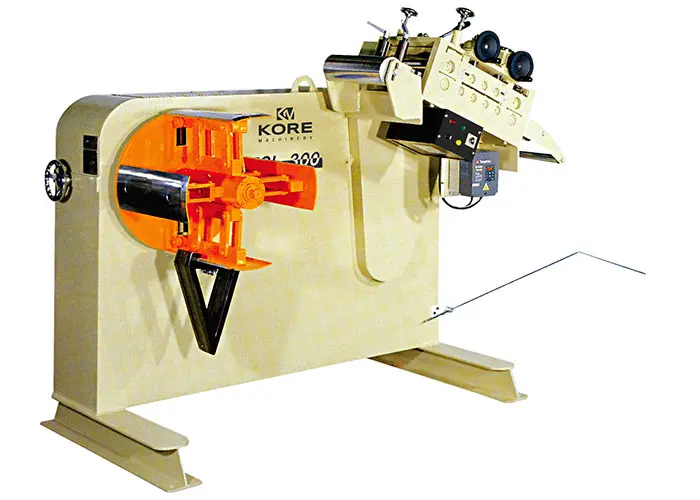

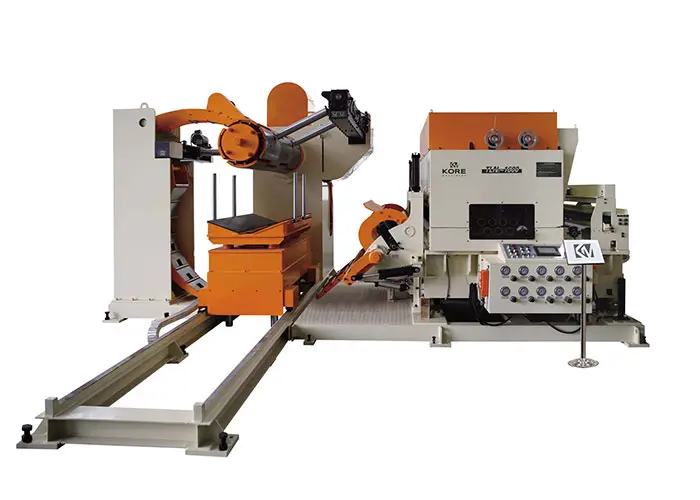

For KORE Machinery, a cut-to-length (CTL) coil line is more than just machinery; it’s a synergy of precision and innovation. Delving into its functionality, a CTL coil line meticulously handles metal coils, beginning with the intricate uncoiling process, progressing to the straightening phase, and culminating in precise shearing to yield sheet metal blanks of the exact required length. Embedded within this process is a high degree of automation, ensuring pinpoint accuracy in feeding, shearing, and flattening, catering to the diverse needs of multiple industries.

Incorporating KORE’s CTL coil lines into fabrication procedures streamlines operations and presents a financial advantage. By doing so, companies can bypass the ancillary costs associated with blank processing, positioning themselves more competitively in the marketplace. It offers businesses a strategic advantage, empowering them to regulate inventory and optimize production timelines through a self-reliant blanking coil line. With this capability, companies can pivot swiftly, producing blanks in necessary dimensions precisely when needed.

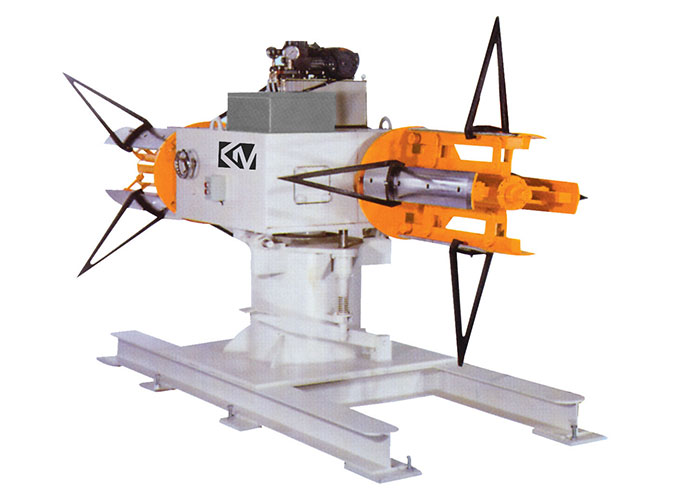

KORE’s distinction lies in its customization. Our cut-to-length CTL coil lines are meticulously crafted, merging our benchmark feeds, straighteners, and reels with KORE’s shearing and stacking solutions. This results in a fully integrated blanking coil line tailored to resonate with specific operational needs. Be it a standard fabrication unit, an Original Equipment Manufacturer (OEM), or a stamping entity, KORE ensures that each CTL line is tailored to the business’s unique requirements.

What Is A Blanking Line?

A blanking line is meticulously designed to convert vast metal coils into precisely defined flat metal sheets, known as ‘blanks.’ These are integral components tailored for subsequent manufacturing steps across diverse sectors.

The process in a blanking line is methodically orchestrated. It starts by unwinding the metal coil and then straightening it to remove any irregularities or twists. Once aligned, the metal journeys through sharp, precision shears, producing the specified blanks.

Incorporating a blanking line within a manufacturing setup allows for more direct oversight over production flow. Firms can promptly respond to market shifts, guaranteeing timely access to the exact size and volume of blanks. This efficiency streamlines production timelines, and curtails costs related to sourcing pre-fashioned blanks.

For those in the industry, the adaptability of blanking lines is paramount. They’re crafted to resonate with the unique demands of various manufacturers, whether they serve niche markets or hold expansive industrial footprints. Even though KORE Machinery does not manufacture these lines, our ethos aligns with ensuring top-tier quality and sustained client support in all machinery endeavors.

What’s Best For You?

In the intricate world of metal processing, understanding the nuanced differences between a cut-to-length line and a blanking line is pivotal. While both systems may seem to converge in function, they serve distinct roles. A blank is a precision-cut piece tailored to fit seamlessly into the subsequent manufacturing phase without further shearing. On the contrary, a sheet is a standard-sized metal piece, often requiring another shear before utilization.

Cut-to-length lines are predominantly associated with sheet production. At the same time, Blanking Lines—furnished with high-precision feed systems and tools like Edge Trimmers or In-Line Slitters—have the versatility to churn out both sheets and close-tolerance blanks. The crux of their distinction lies in the measuring system each incorporates.

Navigating these terminologies can be challenging, with prevailing misconceptions often rooted in assumptions or interpretations. Yet, with diligent examination, clarity emerges. As enthusiasts and practitioners in this domain, it’s crucial to fortify our understanding of the solid bedrock of accurate insights.

In pursuit of uncompromised quality and precision? Explore KORE Machinery’s cut-to-length lines, tailored for those who demand nothing but the best in metal processing. Dive deeper into our offerings and let our expertise be the catalyst for your success. Call now for immediate assistance! (419) 351-6208