Metal Processing with Cut-to-Length Lines

Cut-to-Length lines, often called CTL lines, are pivotal machines in the metal processing industry. They convert coil rolls into precise lengths of sheet metal blanks, encompassing several stages, including uncoiling, straightening, shearing, and stacking.

The CTL line begins with a master coil sourced from an integrated or mini mill. The coil is unrolled, leveled, and then accurately sheared into individual sections of predetermined lengths, ensuring consistency in the dimensions of the sheet metal blanks.

CTL lines are primarily used in processing flat-rolled steel or steel coils, converting the coil into sheets of a specified length. This efficient transformation allows producing sheets to be ready for various applications, including manufacturing, construction, and fabrication.

Role of Cut-to-Length Lines in Metal Processing

Cut-to-Length lines are critical in the metal industry, transforming coiled metals into precise-length pieces ready for sale or further processing as per specific requirements. This capability is highly valued in the metal industry, enhancing productivity, precision, and cost-efficiency.

Cut-to-Length lines bring automation and streamlining to sheet metal production, resulting in several advantages, such as increased productivity, improved accuracy, and reduced material waste. In addition, by precisely cutting metal coils into the required lengths, CTL lines enable manufacturers to optimize material usage and minimize scrap, thereby enhancing overall operational efficiency.

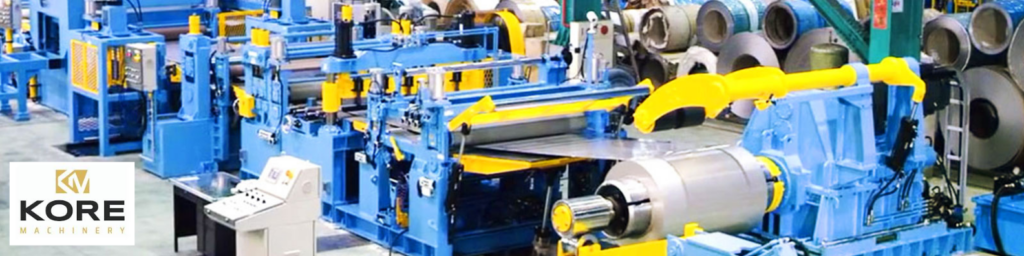

KORE Machinery provides versatile, advanced cut-to-length line solutions, serving a wide array of industries such as automotive, aerospace, agriculture, construction, HVAC, white goods, energy, IT & communication, and service centers, delivering custom-length sheet metal blanks tailored to specific project requirements.

Incorporating Advanced Technologies

In recent years, integrating advanced technologies, such as computerized controls and automation systems, into CTL lines has further elevated their efficiency and precision. Faster setup times, real-time monitoring, and cutting parameter adjustment ensure consistent, accurate results.

At KORE Machinery, our Cut-to-Length lines embody these advancements. Our machines offer superior capabilities, from processing various materials to handling varying coil weights, strip widths, and thicknesses. In addition, integrating state-of-the-art features, like our Precision 6-Hi Cassette Style Leveler and Servo Feed Roll, ensures our CTL lines deliver unmatched precision and productivity.

As technology continues to evolve, KORE Machinery remains at the forefront, adapting and integrating these advancements into our machines. Explore our range of equipment tailored to your specifications, and let us revolutionize your metal processing operations.

Expertise in Cut-to-Length Lines

KORE Machinery is a leading provider of superior cut-to-length lines specifically designed to accommodate an array of materials, including stainless steel, aluminum, hot-rolled, cold-rolled, and surface-treated metals. Our advanced machines can process coil weights up to 80,000 lbs. (35,000 kg), strip widths reaching 96″ (2438 mm), and strip thicknesses up to 1″ (25 mm). In addition, these systems can achieve production speeds up to 275 ft/min (80 mpm), thus ensuring high productivity.

Our cut-to-length line encompasses the following:

- Uncoiler: The uncoiler, integral to the system, accommodates a coil I.D. range of 20″ – 24″ (508 mm – 610 mm). It employs an AC Servo Motor for constant automatic back tension and incorporates Regen drives, reducing energy consumption by up to 75%. The system also boasts an automatic Center Guide System for precise coil height and centerline adjustment.

- Strip Feeding System: This system employs an electrically driven hold-down roll in conjunction with a coil peeler for efficient, autonomous strip feeding. A breaker roll unit promptly straightens the material during the threading process.

- Crop Shear: Our crop shear features automatic indexing, promoting optimal cropping efficiency. It is complemented by the EZ Dump scrap bin with powered removal for effortless scrap management.

- PVC & Paper Application: Our systems provide the option of PVC and paper application to safeguard your material’s surface during the processing phase.

- Edge Trimmer: The Edge Trimmer includes a motorized knife gap setting controlled through an HMI display and a powered conveyor scrap winder for seamless scrap removal.

- Precision 6-Hi Cassette Style Leveler: Our leveler incorporates an automatic cassette exchange system, 19 leveling rolls in a 6-Hi structure, and an independent drive system to mitigate internal stresses. Furthermore, adjustable back-up rolls are included to rectify specific shape defects such as coil sets, crossbow, center buckle, and edge wave.

- Looping Pit Threading Tables: These threading tables enable automatic positioning, facilitating the threading and tailout processes.

- Servo Feed Roll: The Servo Feed Roll utilizes precision servo control to ensure smooth operation, optimal tolerances, and heightened productivity. It allows for indexing speeds of up to 600 ft/min with accel/decel rates reaching 1,000 ft/min/sec.

- Prime Shear: Our prime shear guarantees a length tolerance of .010” (0.3 mm), capable of making up to 60 cuts per minute. An automatic blade gap adjustment is available via the HMI display.

- Piler/Stacker: The Piler/Stacker comprises pivoting runout conveyors with automatic scrap discharge and a double stacker design to enable continuous operation. It includes a pneumatically cushioned end-stop with a tamper for neat stacking and automated, electrically driven lift tables and runout conveyors.

Rely on KORE Machinery for your cut-to-length line requirements. Our exceptional standards in cost control, planning, scheduling, and project safety assure project success—experience how our bespoke equipment can enhance your business efficiency.

Contact us today to explore our selection of new or used equipment tailored to your specifications.