Decoilers Explained

Decoilers, integral components of coil processing lines, are machines specifically designed to unwind coiled metal so it can be processed further—through cutting, straightening, forming, or feeding into other equipment. These machines are foundational to efficient coil handling operations, ensuring that metal flows smoothly into the next phase of manufacturing without damaging the material or compromising line speed.

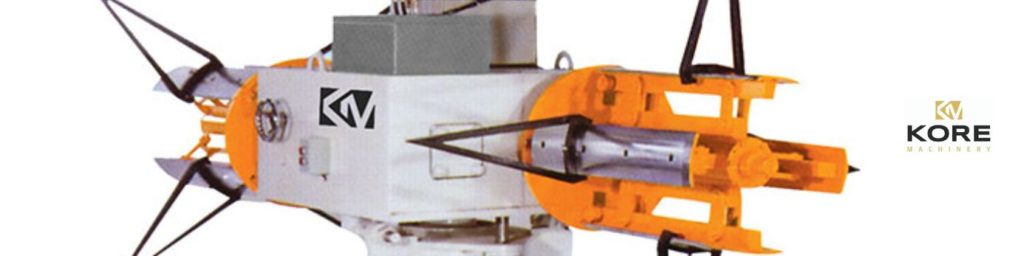

There are several types of decoilers, each suited to specific production needs and coil specifications. Common variations include cone decoilers, single mandrel decoilers, and dual mandrel decoilers. These are selected based on coil weight, width, thickness, and the level of automation required.

-

Cone and dual mandrel decoilers are typically used in heavy-duty applications involving thicker, heavier coils. Their robust design supports stable handling of dense materials often seen in construction or industrial equipment manufacturing.

-

Single mandrel decoilers are widely used for their versatility, accommodating a range of coil sizes and weights while offering straightforward operation and lower space requirements. They are especially popular in general metal fabrication and mid-volume production lines.

Components and Design

The core of any decoiler is the mandrel, a central spindle that holds and rotates the coil. It expands hydraulically or mechanically to grip the coil securely by its inner diameter. This adjustability ensures compatibility with various coil sizes and minimizes slippage during unwinding.

A coil support system—which may include a coil car, side supports, or hold-down arms—helps maintain alignment and supports the weight of the coil during operation. Depending on the production line layout, some decoilers also include braking systems or tension control mechanisms to maintain proper speed and prevent uncontrolled unwinding.

Once the coil is secured, the decoiler unwinds the material, feeding it into downstream equipment like straighteners, feeders, or shears. Controlled and consistent unwinding is vital for maintaining material integrity, avoiding deformation, and ensuring smooth line operation. The precision of this stage directly affects productivity, scrap rate, and overall process efficiency.

Material Handling Capabilities

Modern decoilers are engineered to handle a wide range of coil materials and dimensions, adapting to the varied demands of today’s manufacturing environments. Key capabilities include:

-

Various Metal Gauges: Decoilers can process light-gauge metals such as aluminum and thin stainless steel, which require gentle handling to avoid creasing or bending. At the same time, they can accommodate much heavier gauges used in high-strength or structural applications.

-

Heavy and Thick Steel Coils: Decoilers built for heavy-duty tasks feature reinforced frames, large-diameter mandrels, and high-torque drives to manage the weight and strength of thick steel coils. These systems are ideal for use in industries like construction, shipbuilding, and agricultural equipment manufacturing.

-

Coated or Sensitive Materials: Some decoilers include features such as protective rollers, anti-scratch surfaces, or tension control systems designed to preserve the finish of delicate materials.

Maintenance and Safety Protocols

To maintain consistent performance and prolong machine life, routine maintenance is essential. This includes regular inspection of moving parts, timely lubrication of the mandrel and expansion system, and replacement of worn components before they affect operation.

Equally important are robust safety protocols, especially when working with heavy coils and high-speed lines. Best practices include:

-

Operator training on machine controls and emergency procedures

-

Use of safety guards, coil containment arms, and limit switches

-

Lockout/tagout procedures during maintenance

-

Scheduled safety audits to identify and mitigate risks

These measures not only protect the equipment and product quality but also reduce the risk of injury, ensuring a safe and compliant working environment.

Decoilers in Different Industries

Decoilers are critical in many industrial sectors where coil-fed metal processing is used. Decoilers support high-volume, high-precision production by delivering flat, properly fed material into forming, cutting, or stamping systems.

Here’s how decoilers support key industries:

-

Automotive: Decoilers feed coils into stamping presses or forming lines used to manufacture car body panels, frames, brackets, and structural components.

-

Construction: They unwind heavy-gauge materials for roofing panels, studs, cladding systems, and structural beams.

-

Aerospace: In applications requiring exacting tolerances, decoilers provide smooth, tension-controlled feed to ensure the material quality needed for aircraft parts.

-

Appliances & White Goods: Decoilers feed pre-finished metals into press lines for appliance housings and internal components.

Their role in enabling uninterrupted material flow makes them indispensable to efficient, large-scale metal part production.

Need Profesional Help?

Selecting the right decoiler is a critical decision that affects throughput, safety, and long-term equipment ROI. Choosing a system that aligns with your operation’s coil dimensions, material types, line speed, and space limitations is essential for optimal performance.

KORE Machinery offers a wide range of decoiler configurations designed to meet diverse industrial needs. Whether you’re upgrading existing equipment or building a new coil line, our experts will help evaluate your production goals, budget, and technical requirements to recommend the ideal solution.

Reach out to us today for personalized advice and to learn more about our range of high-quality coil handling equipment.