Where Metal Processing Meets Innovation

The metal processing world is buzzing with new challenges and opportunities, all thanks to the ever-changing demands for better precision, more efficiency, and greater versatility in metal forming. KORE Machinery, a true pioneer leading the charge in coil processing innovations, is at the head of this exciting evolution.

In this article, we’re diving into the heart of what KORE Machinery offers and how our cutting-edge solutions are tackling the latest challenges in coil processing head-on.

Cutting Sheet Metal

KORE Machinery’s Cut-To-Length (CTL) Lines represent engineering excellence designed to alter coil rolls into sheets of specified lengths with complete accuracy. These lines are equipped to handle a variety of materials, including stainless steel, aluminum, and specialty red metals, catering to a wide range of industry applications.

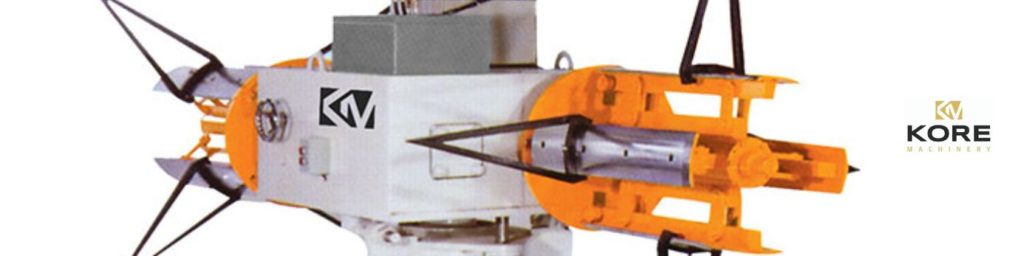

The rotary shear cut-to-length line, in particular, shows KORE’s commitment to advanced technology and tough design. It guarantees swift, precise cuts, ensuring top-tier efficiency, especially in processing specialty steel and red metals. This innovative approach enhances production capacity and reduces waste, marking a significant leap in viable manufacturing practices.

Redefining Material Processing

KORE’s Slitting Lines set the standards of material processing, expertly engineered to handle a wide variety of materials with unequaled efficacy. These machines can manage impressive coil weights up to 80,000 lbs. and accommodate strip widths up to 96 inches, demonstrating our commitment to flexible, high-performance machinery design.

Key features ensure each slitting operation is executed with maximum precision and productivity, such as:

- Uncoiler with AC Servo Motor Drive: Provides constant back tension, ensuring accurate and consistent uncoiling.

- Precision Flattener: Improves coil shape and reduces residual stress for better end-product quality.

- Adaptable Looping Pit: Adjusts loop depth based on material characteristics, enhancing the precision of the slitting process.

Press-Feeding and Coil Handling Systems

Regarding press-feeding and coil handling, KORE Machinery introduces next-generation efficiency with state-of-the-art equipment.

The 3-in-1 NC Servo Straightener Feeder with Uncoiler exemplifies high precision and changeability, addressing the needs of modern manufacturing lines that demand flexibility and performance.

Similarly, the 2-in-1 Type Precision Uncoiler/Straightener showcases KORE’s ability to engineer solutions that enhance material handling and precision in diverse applications.

These systems are pivotal in reducing waste, improving throughput, and significantly boosting the overall efficiency of production processes, cementing KORE’s role as a catalyst for innovation in the metal processing sector.

Industries That Use Our Products

At KORE Machinery, we’re passionate about pushing the boundaries in metal processing with our cool techs like Cut-To-Length, Slitting Lines, and some impressive Press-Feeding and Coil Handling Systems. Designed to hit the mark on precision, speed, and flexibility, our machinery is here to meet the needs of many industries, from cars and planes to farming and building. We’re all about innovation, making sure you’ve got the best tools in the biz to keep your operations humming and ahead of the curve.

So, whether you’re crafting the next generation of vehicles, designing sleek aircraft, or providing energy, we’ve got the machinery to amp up your production and boost your efficiency.

Ready to Work Together?

Looking to enhance your production processes and achieve greater operational productivity? KORE Machinery is at the forefront of innovation, ready to collaborate with businesses aiming to upgrade their metal processing capabilities.

Contact KORE Machinery today to explore how our advanced coil processing solutions can be integrated into your contemporary manufacturing environment. Let’s work together to reveal new possibilities for your operations.