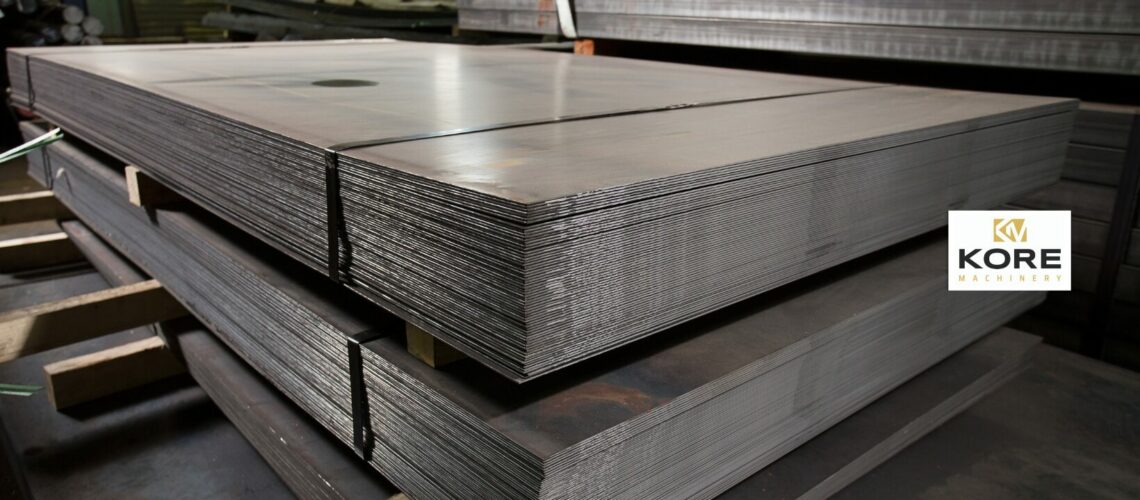

Sheet Metal Integration in Industrial Practices

Sheet metal, a broad classification of metal formed into thin, flat pieces, is necessary in numerous industries due to its adaptability. Its ability to be easily molded, cut, bent, and stretched into various shapes makes it indispensable for manufacturing components in automotive, construction, healthcare, aerospace, and electronics.

The benefits of sheet metal include its lightweight nature, durability, high strength-to-weight ratio, and cost-effectiveness, making it suitable for high-strength applications and intricate designs. Additionally, sheet metal offers excellent corrosion resistance and can be customized to meet specific requirements, enhancing its utility in diverse environments, from harsh agricultural conditions to sterile medical settings.

KORE Machinery is a leading manufacturer of sheet metal processing equipment. Learn more about the industries where you can find our machinery.

1) Automotive

In the automotive industry, sheet metal is pivotal in manufacturing vehicle components. It is used to create car bodies such as doors, hoods, and roofs, as well as structural components like chassis and engine mounts.

Additionally, sheet metal is cost-effective and can be easily formed into various shapes, streamlining the manufacturing process and allowing for efficient mass production. These advantages enhance the performance and reliability of automobiles and help manufacturers effectively meet industry standards and consumer demands.

2) Agricultural

Sheet metal is critical in producing farm equipment and machinery, offering needed components that enhance longevity. Its applications include:

- Engine components, body kits, and fenders.

- Agricultural fan cowls.

The benefits of using sheet metal in these areas are:

- Durability in harsh weather conditions.

- Efficient and reliable performance, ensuring consistent productivity in agricultural operations.

3) Construction

Sheet metal is necessary in construction to provide structural support and cladding in building frameworks, roofing, and wall applications. Its use ensures strong and consistent structures that withstand environmental elements such as wind, rain, and temperature fluctuations. The material’s endurance and permanency make it a model choice for protecting buildings, offering aesthetic appeal and practical benefits by maintaining structural integrity over time.

For instance, it is used to create roofing panels, gutters, and flashing, all contributing to a building’s overall weather resistance.

4) Electrical

Sheet metal is crucial for component fabrication in the electrical industry. It is used to create casings and shielding for electronic devices, as well as parts for power generation and solar energy systems.

The material’s ability to be customized for specific applications ensures that it meets precise requirements, while metals like copper offer excellent electrical conductivity, making them ideal for these purposes. This versatility and functionality make sheet metal indispensable in producing reliable and efficient electrical components.

5) Healthcare

Sheet metal is essential in the healthcare industry, providing the foundation for various medical equipment and tools. Its applications include:

- Surgical Instruments: Precision-crafted tools used in various medical procedures.

- Hospital Beds: Durable and adjustable frames ensuring patient comfort and safety.

- Medical Cabinets: Secure storage units for medications and medical supplies.

- Sterilization Equipment: Devices and containers designed to maintain strict hygienic standards.

6) Aerospace and Aviation

In aerospace, sheet metal is indispensable for manufacturing aircraft components, such as structural parts and engine components, where lightweight materials like aluminum are prevalently used. The selection of aluminum and other lightweight metals significantly contributes to weight reduction, enhancing fuel efficiency—a crucial factor in aircraft design.

Moreover, these materials offer high resistance to corrosion and wear, ensuring the durability and safety of aircraft under rigorous flight conditions. This combination of lightweight, strength, and efficacy is required to meet the stringent aerospace engineering standards.

7) Consumer Goods and Home Applications

Sheet metal is widely used in household appliances and décor, including kitchen countertops, appliances, and decorative screens.

Its aesthetic appeal and customization options enhance home interiors and inspire homeowners to create unique and stylish living spaces. The material’s ease of maintenance makes it a practical choice for everyday use, offering homeowners style options.

8) Emerging Technologies

Sheet metal is increasingly imperative in emerging technologies, particularly in integrating automation and robotics. It’s used in the development and manufacturing of:

- Automated Machines and Tools: Sheet metal components are essential in automated systems used in manufacturing, packaging, and more, enhancing productivity and operational efficiency.

- Precision Parts for Advanced Technologies: The material’s adaptability allows for creating highly precise parts necessary for cutting-edge technological applications, such as robotics and advanced engineering systems.

Need Sheet Metal Fabricating Equipment?

We’re dedicated to enhancing your production with state-of-the-art sheet metal forming solutions at KORE Machinery. Whether you’re in the automotive, aerospace, or any other industry, our precision equipment is designed to meet your unique needs.

Reach out to learn how our advanced slitting lines and advanced technology can alter your operations.